Fatigue design of the shaft of a mixing plant

The customer

Industrial group specialized in lead and zinc metallurgy.

Scope of work

Fatigue assessment and design of the shaft of a mixing plant for conglomerate.

At a glance

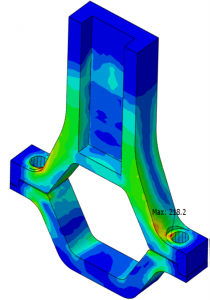

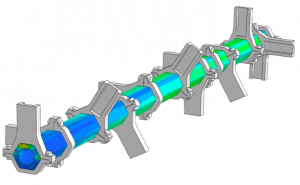

A mixer system is acted by means of a shaft. Through a system of plowshares, the plant stirs a conglomerate charge. Due to high dynamic stresses, the shaft underwent frequent breakings, forcing the plant to continuous maintenance. ASTARTE performed an analysis on the component by means of numerical modeling, confirming the fatigue issues and identified most critical regions. With the help of FEA technologies integrated with fatigue forecasting models, a new shaft was designed which embed new solutions allowing a sharp reduction of stresses in critical regions and a prolonged operation up to a virtually indefinite fatigue life.

Results

The new shaft is globally redesigned. In addition to a new cross section, the new joining system with plowshare holders involves the replacement of welded joints with flanged systems.