TECHNOLOGIES

Customized solution

Each customer brings his own needs, espectations, aims. ASTARTE proposes ad hoc strategies to develop your idea of innovation.

Interaction and flexibility

Our projects include milestones for meeting, verification and discussion with the customer. Let’s plan together any rerouting intervention to assure the goal accomplishment.

Reliability

Costs and times certainty, sure results.

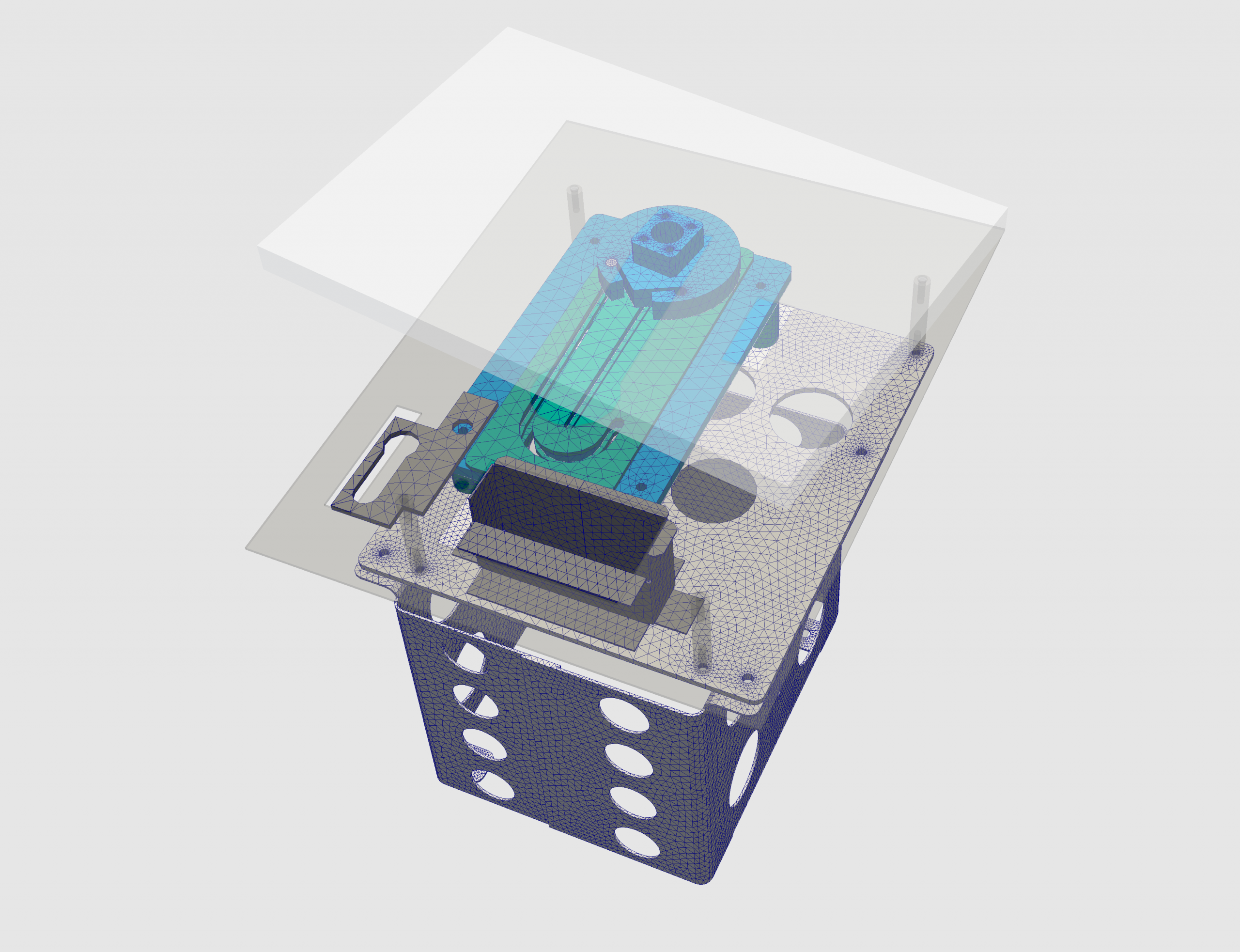

Structural Analysis – FEA

The team owns large experience in the application of state-of-art codes for structural numerical analysis and in the development of ad hoc models to simulate each specific cases. Our customers are assisted by advanced competences to build solid and reliable solutions.

- stress-analysis

- fatigue assessment

- low cycle fatigue

- elastic-plastic assessment

- large deformations

- Strain-Based Design

- assessment against dynamic loads

- thermal structural analysis

- buckling

- modal analysis

- magnetic loads analysis

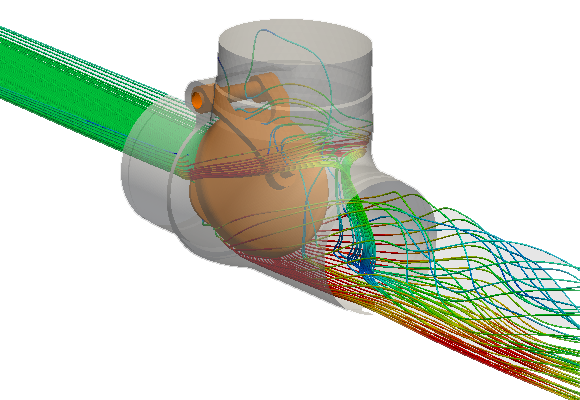

Computational Fluid Dynamics – CFD

The recourse of numerical codes for fluid dynamics analysis is a strategic option for the understanding of complex systems. ASTARTE makes use of CFD codes for the analysis of the evolution of fluids in mechanical components, industrial plants, buildings and for the environmental impact of anthropic activities.

- aerodynamics

- fluid dynamics

- piping and pipeline

- turbomachinery

- combustion

- thermal heaters

- biomedical application

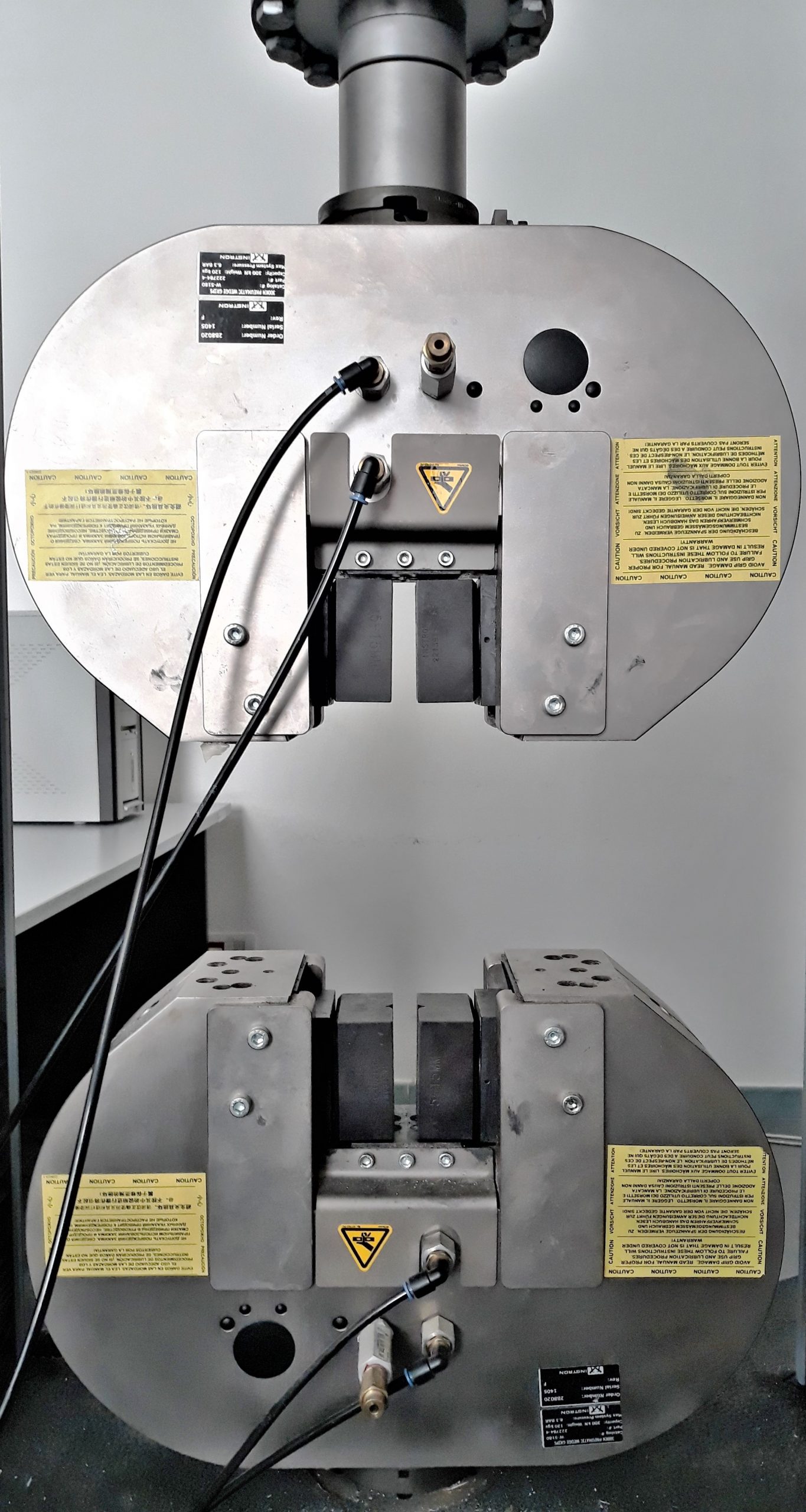

The Laboratories – Testing

Experimental investigation is an essential issue in the frame of supporting design and innovation. Lab testing is required to characterize the properties of materials, components and to support the set up of numerical models.

In this frame ASTARTE owns advanced capabilities including testing design, execution and data interpretation. The close cooperation with the laboratories of the Department of Mechanical, Chemical and Materials Engineering of the University of Cagliari makes available high-cut competences and advanced testing machines.

- facilities for material mechanical characterization: servo-hydraulic machines, servo-electrical machines, drop weight tear test rig

- heat exchange laboratory

- turbomachinery testing lab

- technical acoustics

- non-destructive investigation: x-ray and ultrasonic inspection, optical 3D deformation analysis (DIC), interferometric systems;

Moreover, ASTARTE cooperates with a network of national and international laboratories with acknowledged competences, to ensure services with high level of quality.