ASTARTE offers customized solutions for plants and processes optimization by recurring to advanced analysis tools and by taking advantage of the experience gained in a large number of industrial fields.

PROCESS ENGINEERING

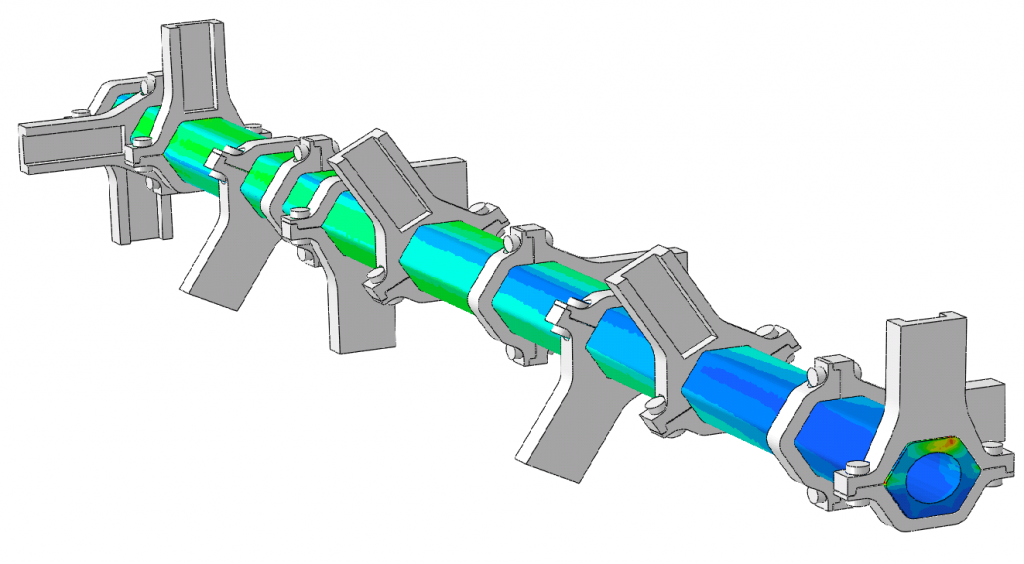

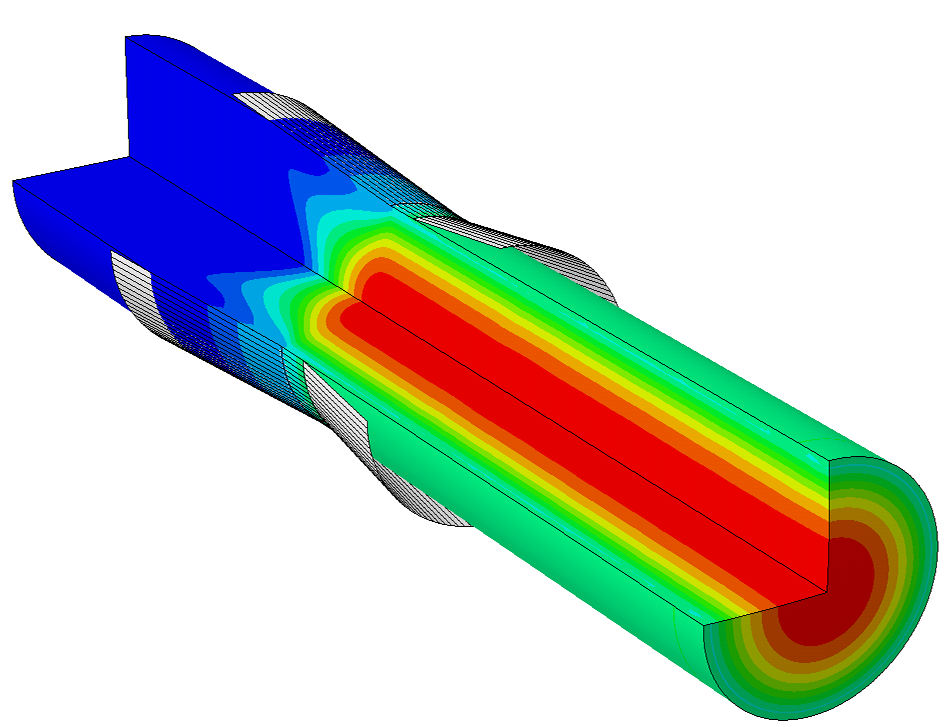

Metalworking processes

Cold drawing and rolling are mechanical processes allowing manufacturing high performance products. Those processes are extremely sensitive to the operational parameters and an erroneous plant setup may prevent from meeting the product requirements and/or the product failure, i.e.: the production slow-down.

The application of ad hoc analysis allows to:

- determining plant setup assuring the products required performance;

- improving the plant performance in terms of loads, temperature, etc.

- optimizing the whole manufacturing process: working time, maintenance interventions, etc.

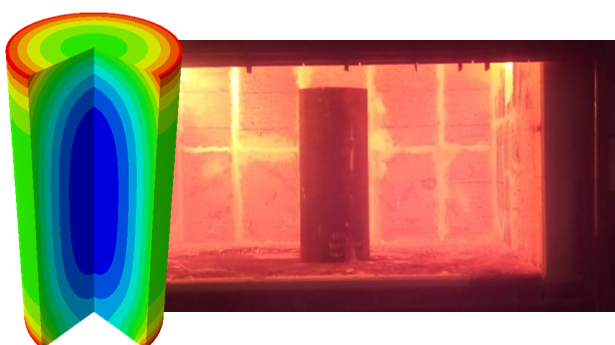

Heating furnaces: thermo-mechanical effects

Heating processes for steel ingots is a step preliminary to metalworking and it implies large expenses both in terms of time, and in terms of fuel consumption.

However, by means of a customized process numerical modeling, procedures are developed which allow to:

- reduce the working time

- depleting the fuel consumption

Plant maintenance

Due to the changing production needs, the plants might be required to face new and more severe operating conditions. Inappropriate re-design may result in inadequate performance levels as well as in frequent failures.

By means of structural and/or fluid-dynamics numerical simulations, the critical elements are properly re-designed to prolong the service life, avoid/reduce downtime, mitigate the maintenance costs and improve the plant efficiency.