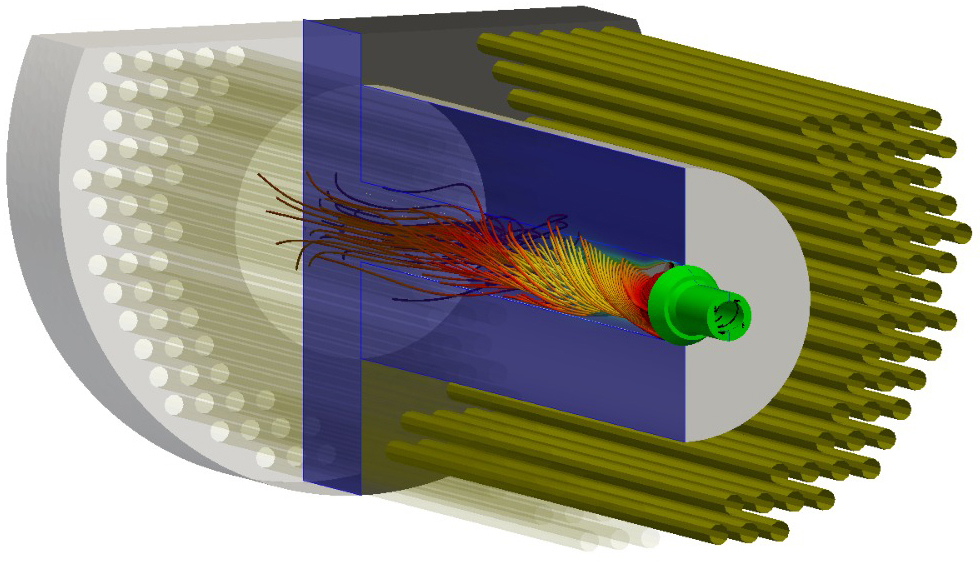

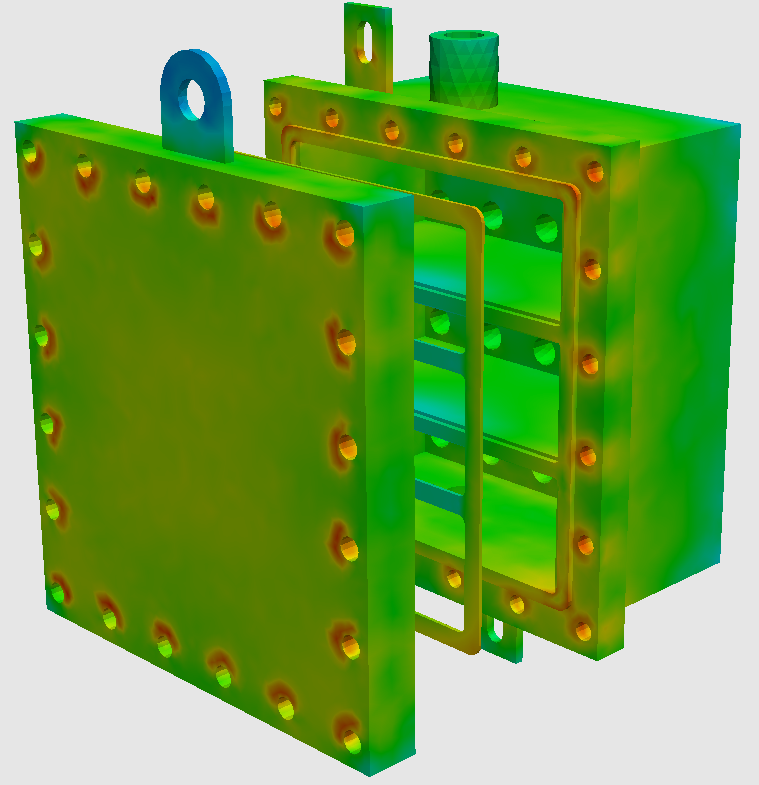

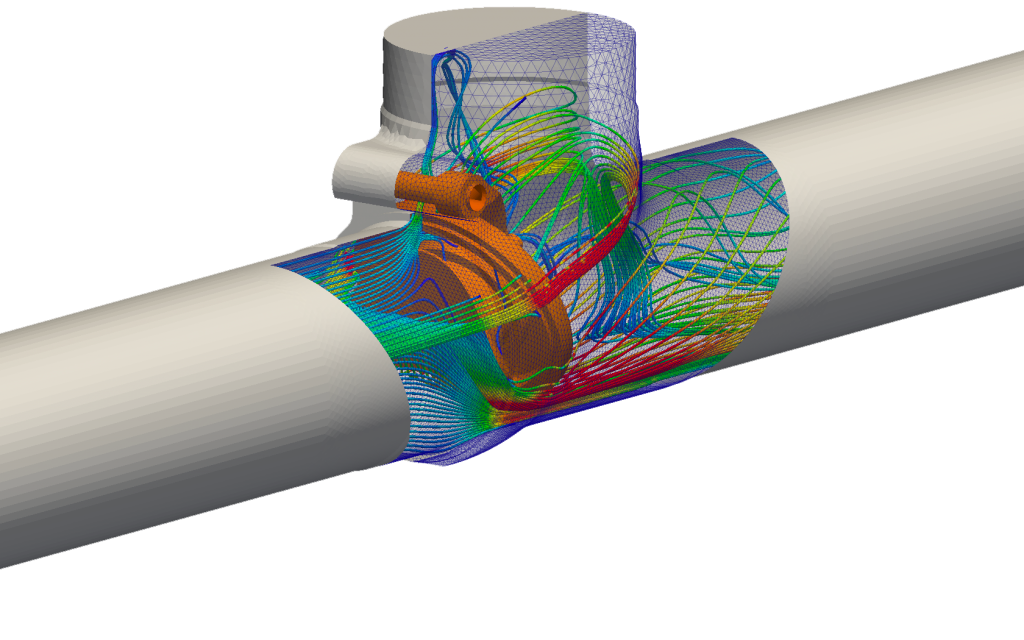

Experimental-numerical joint methods are strategic options for promoting the efficiency of energy production, transportation and utilization plants, as well as for developing solutions for mitigating pollutants production.

The virtualization of the processes allows analysing and monitoring wide spectrum of scenarios: preliminary analysis, design, operating life, accidental events.