Thermo-structural modeling of pre-forging heating of steel input stocks

The customer

Leader in hot rolling, forging and molding processes for a wide range of steels.

Scope of work

Production optimization and product quality enhancement.

At a glance

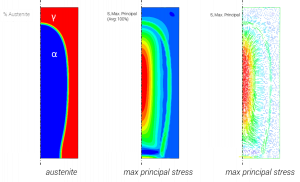

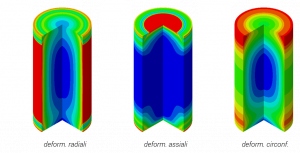

The preheating of steel blocks for subsequent thermoplastic processing is a costly process, in terms of both time and fuel consumption. Therefore, an interest is ackowledged in reducing processing times, containing consumption and avoiding thermal shocks threaten the structural integrity of the blocks. ASTARTE developed and validated a numerical model. For each heating procedure set, the model can predict:

- the evolution of the temperature in the furnace and in the blocks

- the deformations and thermal stresses to which the material is subjected

Results

The application of the model allows to optimize the heating procedures to contain the process times, provide indications on fuel consumption and reduce the risks of break due to thermal shock in the blocks.